Review Article

Austin Chem Eng. 2023; 10(3): 1104.

Mechanical and Morphological Characteristics of Nickel, Chromium and Nitride-Based Coatings Formed via Electrodeposition and Magnetron Sputtering Techniques on Mild Steel. An Overview

Jahanzeb Bhatti1*; Ali Dad Chandio1; Quazi MM2; Bashir MN3; Rizwan M1; Iftikhar Ahmed Channa1; Abdul Rauf Jamali4; Fayaz Hussain Katper5; Imran Ali6

1Department of Metallurgical Engineering, NED University of Engineering and Technology, Pakistan

2Faculty of Mechanical and Automotive Engineering Technology, Universiti Malaysia Pahang, Pekan, Pahang, Malaysia

3National University of Sciences and Technology (NUST) Islamabad, Pakistan

4Department of Materials Engineering, NED University of Engineering and Technology, Karachi

5Modeling Evolutionary Algorithms Simulation and Artificial Intelligence, Faculty of Electrical & Electronics Engineering, Ton Duc Thang University, Vietnam

6Institute of Metal Research, Chinese Academy of Science, Shenyang, China

*Corresponding author: Jahanzeb Bhatti Department of Metallurgical Engineering, NED University of Engineering and Technology, Pakistan. mail: engineerjahanzeb@gmail.com

Received: July 18, 2023 Accepted: September 15, 2023 Published: September 22, 2023

Abstract

Mild Steel (MS) is considered as the most widely employed engineering material, which is primarily being used in an automotive industry. Several parts including fuel system, outer and body panel, trims, chassis exhaust, along with many other parts are made up of MS. The driving force behind versatility of MS is its unique set of characteristics. However, the issues arise when its tribological degradation occur that creating problems in service conditions. The best solution for this problem is to coat the mild steel with transition metal-based nitride coatings such as, Ni and Cr. Insufficient Literature is available related to the mechanical performance of single/gradient layer (Ni, Cr) N ternary coating on mild steel substrate. Current review focuses on the characteristics of the coatings that are deposited through two different deposition techniques; electrodeposition and magnetron sputtering. The studied coatings materials are nitrides of nickel and chromium, deposited in several layers. Furthermore, the structural and mechanical properties of these coatings have been compared.

Keywords: Structural properties; Mechanical properties; Electrodeposition; Magnetron sputtering; Nitride formation

Introduction

The current growth in the automotive, biomedical, and aerospace and a variety of processing industries demand materials exhibiting improved mechanical performance under severe operating conditions. Mild steel has served as the most integral part of these industries for few decades, owing to its ductility, formability, weldability and reasonable mechanical strength [1,2].

However, monolithic materials are unable to fulfill the synergistic demands of special applications. Here comes the role of surface engineering, which offers enhancement in tribological and mechanical characteristics of conventional materials. This is the reason why so many researchers have focused in recent years to tailor the surface characteristics using several coating techniques. These coatings enhance the tribological performance along with corrosion resistance by serving as an interface between working environment and the substrate [3-5].

Currently various coating techniques have been employed successfully amongst which Electrodeposition (ED) and Physical Vapor Deposition (PVD) are considered as the most prevailing procedures to acquire enhanced hardness, adhesion strength of coating-substrate, control of chemical composition, good surface finish [6-9]. Electrodeposition (ED) mainly sub-divided with respect to bath composition and working parameters. In ED, Watt’s bath is considered as the simple, more controlled and economical deposition method. Whereas in Physical Vapor Deposition (PVD,) the most efficient technique is magnetron sputtering having better coating adhesion to substrate, good control of the temperature and composition, lower thermal shock [10] and ability to use a number of target materials [11].

Significant research interest has been received by automotive industries for the enhancement of mechanical/ tribological properties using metal (such as Al, Ti, Mg, Ni & Cr) transition nitrides as coating materials. Amongst monolithic materials, transition metallic nitride coatings such as nickel, chromium and nitrogen seem to have comprehensive and better properties for automotive and decorative applications [5,12-15]. Due to its attractive properties such as, magnetic properties, toughness, corrosion resistance, wear resistance and hardness, Nickel has received spike in research attention [16,17], and is employed widely as corrosion resistant deposition material [7]. For this purpose, nickel electroplating is more convenient technique [18]. Besides Ni, binary compounds of transition metals (such as Cr N, TiN and NiN etc.) have been used in automotive sector for various applications. CrN is considered as the most suitable coating material from this family. Basic research has been done on physical and mechanical properties of these thin films and give evidence that they possess extremely high hardness, high temperature resistance to oxidation, wear and fatigue resistance, low coefficient of friction [19-24], and good surface finish [25-28]. PVD or more favorably reactive magnetron sputtering is employed most commonly, in order to deposit CrN coating [29]. Several researchers have attempted to improve overall coating properties through various possibilities, for instance single layer [30], bilayer [22], and gradient layer [31-34]. In order to improve wear and corrosion resistance, single layer coatings are commonly deposited on biomedical implants and cutting tools [21] and are very easy to form without incorporating and adjusting phase formation. Bilayers and gradient coating tends to sustain much residual stresses with better corrosion resistant, mechanical and tribological properties, higher resistance to cohesive and adhesive crack propagation as compared to single layer, moreover they possess very fine grain size and almost free of micro cracks and many other defects [35]. So, the combinatorial effect of bilayer electrodeposition and magnetron sputtering provides better coating, superior to individual technique.

Catastrophic coating failure can be avoided by preparing a hybrid system of materials comprising of a harder superficial layer on a tougher coating material [25]. Till date, the effect of combining Ni & Cr has not been studied adequately. The development of CrNiN thin film was carried out using unbalanced magnetron sputtering (closed field) for the components critical for safety [36], magnetic layers [37] and for applications related to cutting tools [38]. However, scarce literature is available, comparing mechanical performance of the single and gradient layer (Ni, Cr) N ternary layer deposited on the mild steel substrate. This study is aimed at reviewing the mechanical performance enhancement of the mild steel substrates using (Ni, Cr) N ternary layer.

A comparative evaluation of the mechanical performance (surface hardness, film-to-substrate adhesion friction coefficient and roughness) is carried out in this review, in relation to the composition and morphology of the (ED Ni) single layer, (ED Ni + magnetron sputtering CrN) bilayer, (PVD CrNiN) single layer and (PVD Ni/NiN/ Cr/CrN/NiCrN) gradient layers deposited on the MS substrate.

Materials for Automotive Industry

Advancement and development in automotive industries is being carried out for 100 years. Time by time extensive features and performance has been developed. As the time goes by, automotive industry is also growing its demands as per requirement. There are so many reasons to introduce and develop new techniques in an automotive industry. As for controlling of harmful gases from combustion engine, engine management and post treatment expertise follow the principles of some international standards, for instance, European Standard EURO III, American EPA Emission Standards, including CAFÉ standards, and Californian Emission Standards.

Beside that ‘‘Organization Internationale des Constructeurs d’Automobiles’’ (OICA) stated that round about 20 million commercial vehicle and about 53 million cars were produced in the year 2007. In fact, automotive industry is facing many challenges due to environmental factor, quality, reliability, life, functionality, safety, economy and many other factors that would be hard to maintain by keep on improving technical properties. As one of the possibilities to improve the engine efficiency is to reduce the weight of the engine components. For this lighter material may perform better, that are also widely being used just like, Al, Ti, and Mg, are the best materials for an automotive industry. But the problem is that, these materials have poor tribological properties [36-38].

There is a wide range of materials being used in an automotive industry since decades. Different materials are used for different applications and selection of material is very important and difficult task as well. Importance of factors in selecting proper material for automotive design and engineering is shown in Table 1. It is seen that importance of cost reduction, weight reduction, easier manufacturing, better durability, integrated functionality is at the top priority in choosing materials. The rest factors also have the importance level within the range, 50-60% [39].

Factors

Importance (%)

Cost reduction

91

Weight reduction

82

Easier manufacturing

77

Better durability

71

Integrated functionality

63

Simplified design

60

Lower wear and friction

60

Improved appearance

58

Recyclable

57

NVH reduction

56

Proven in previous application

53

Temperature or electrical properties

34

Table 1: Importance of some factors in selecting materials for automotive design and engineering [39].

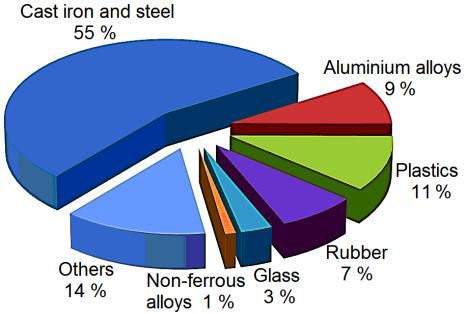

So, keeping in view all of these factors it is crucial to select materials having better properties for an automotive. Though Mg, Al, and Ti are widely used in an automotive industry due to their high strength-to-weight ratio, corrosion resistance, ductility and etc., but they are high in cost. Beside that Steel is another important material that is widely used in an automotive industry. As seen in Figure 1, more than 50% of steel is utilized in an automotive vehicle [40].

Figure 1: Materials used in a vehicle [41].

Steel is used for many applications, in aspect of physical, mechanical, chemical, and several other aspects. As quality and durability is the primary concern for automotive, so steel is preferable to other metallic materials and coatings. Steel has outstanding corrosion resistance property, better look, high strength, durability, hardness, and much more properties [41].

Mild Steel and its Usage in Automobile Engine

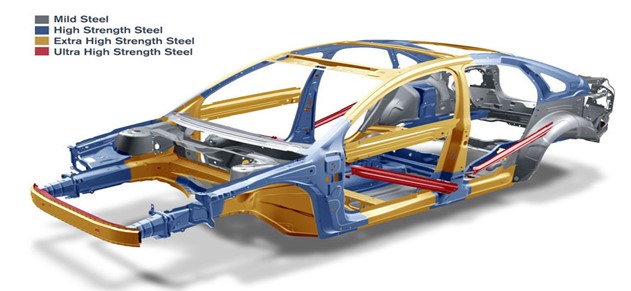

In recent times, with the overwhelming developments in automobile, biomedical, aerospace, electronics and various manufacturing industries, countless materials are being studied in order to enhance mechanical performance under harsh operating conditions. Some manufacturers of the automotive sector also classify the types and maintenance of the steels of specific vehicle that is shown in Figure 2 by a color-coded graph of the vehicle [42].

Figure 2: Different types of steel used in a vehicle [42].

For a broad range of applications, steel is further categorized in a wide range of categories with respect to their composition and physical properties. From the above classification, it is obvious that MS is the most commonly employed structural material for automotive sector [43-47]. So, as far as practical applications are concerned MS is used for engine fuel, outer and body panel, trims, exhaust, etc. [26,48].

Limitations of Mild Steel and Remedial Measures

Though mild steel has attractive set of properties however, wear and corrosion restrict its usefulness [28,49]. In order to overcome these problems, different surface modification techniques are important. Amongst surface treatment or modification, coating is the best alternative to protect the material for diminishing its properties by modifying surface properties. So, coating of mild steel with some other materials like Ni, Cr, NiN, CrN, ZrO, TiN, etc. can significantly improve the corrosion resistance which leads to increased product life [25,50].

Coating and its Importance

It’s worth noted that almost every manufactured product requires a coating to look aesthetic and/or protective purposes. Researchers and Manufacturers are working hard to improve surface properties including mechanical, chemical, electrical, and optical tribological, decorative, functional, corrosion resistance, etc. by applying coating [13]. The use of surface coatings opens up the possibility for a material design where particular properties are located and where they are mostly needed. In an automotive industry the substrate materials are intended to work in the severe environmental conditions, and formation of coatings make it possible to resist the corrosion and to achieve the required functional characteristics [51-53]. Basically, surface treatments are employed for decorative and functional applications. In terms of functional properties, it modifies mechanical, chemical, electrical, and optical properties [3,13,25].

As mentioned before, coatings are very essential for any of the automotive part as coating is a barrier in between environment and substrate. Coating protects the substrate material from several aggressive chemical and mechanical degradations [3] and it’s also imparting color and visual appeal to the substrate [54]. Coating enhances the substrate hardness, scratch resistance, control friction, corrosion, erosion and oxidation resistance, low coefficient friction, increases stiffness and fatigue, it improves thermal insulation, and life of substrate also increased [24]. As the main factor that is to be considered in every industry is the overall cost, maintenance, and life of the material and here for all of these factor’s coatings find their way as they maintain the substrate material from aggressive environmental factors and increase the life. Coating is an important for almost many of the industries just like in automotive, aerospace, petrochemical and marine. One of the most promising consumers of surface technologies is an automotive industry. So various investigations are being carried out to develop advance techniques for life, quality, flexibility, and improvement of automotive materials [55].

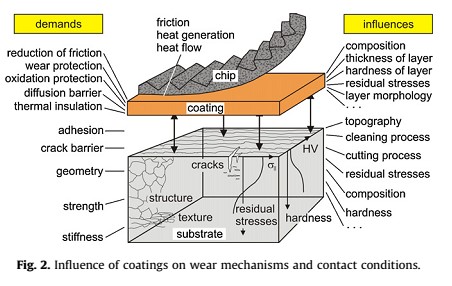

Properties of Coatings

In fact, all of the materials have certain limits beyond which they fail. Application of coating can extend the material life by improving its different properties. Before selecting coatings for an engineering / automotive application, it is very essential to know the properties that can sustain and maintain its practical applications in certain environments. The most important coating properties include structural, mechanical, corrosion resistance, decorative and functional properties. These properties of coating are basically influenced by different factors as shown in Figure 3. The influencing factors for coating material and substrate are composition, thickness, morphology etc. The common characteristics of coating that are expected to be increased are reduced wear and friction, oxidation protection, improved adhesion and strength etc. For selecting any of the coatings it is very essential to know about structural classification of coatings and understand properties and behavior of materials and coatings as well [56].

Figure 3: Factors that affect properties of coatings [25].

Structural properties: Structural properties are essential for surface modification, as they are the basic concern of materials science. It is the surface that directly comes in contact with environment and counter bodies when materials are in working condition so it is necessary to know about surface morphology and phases formed to modify strength. Structural properties are measured through non-destructive measuring techniques [25]. Some of the structural properties include morphology, phase formation, lattice, grain structure, crystallographic structure, amorphous, crystalline and many other structural properties [25,56-58] distributes the structural stages of matter into seven levels (Table 2), and the properties of engineering materials are related to these levels and changes accordingly. In the following section, two major structural properties such as i) morphology and ii) phase formations have been explained.

Level of structure

Size of structural objects (m)

10-15

10-12

10-9

10-6

10-3

10-0

10

Elementary particle

Nucleus

Atom

Molecule

Monomers High polymers

Phase

Small Large elementary cells

Microstructure

Diameter of grain or phase boundary Large grain size

Engineering structure

Integrated circuits Chinese wall

Table 2: The seven levels of structure suggested by [58].

i. Surface morphology

Morphology depends upon the shape, size, and structure of the materials / coatings surface, that how grains of structure are located, about their grain boundary, size of grain, their orientation, surface finishing, and their behavior with respect to size, shape and structure [59]. Surface morphology can be characterized through various surface techniques, just like Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), Scanning Tunneling Microscopy (STM) Atomic Force Microscopy (AFM), etc.

ii. Phase formation

Phase formation is related to the microstructure that changes the mechanical properties, by grain refinement, changing grain size and shape or structure. This may occur through diffusion of particles, maintain phase number and type, e.g., pure metal solidification, allotropic transformation, recrystallization, grain growth, by changing phase composition, by diffusionless, and etc. [60]. Phase structure is normally characterized through Transmission Electron Microscopy (TEM), X-Ray diffraction (XRD), X-Ray Fluorescence (XRF) etc.

Mechanical properties: Mechanical properties are also much essential for engineering materials, as they play an important role and mechanical properties are those that are deformed by the action of a force. It is worth mentioning that performance, durability and life of the materials much depends upon its mechanical properties. Mechanical properties include hardness, wear, friction, malleability, ductility, strength (shear, compressive, tensile), brittleness, adhesion, roughness, and etc. [25,56,57]. Few of these important properties have been discussed below.

i. Hardness

Hardness is one of the very crucial mechanical properties. It has to be taken for almost all of the materials / coatings used in an automotive industry. In an engineering hardness may be defined as the resistance of a material to penetration [61]. Generally, hardness of materials is increased with decreasing the depth of penetration and that is known as Indentation Size Effect (ISE) [40,61]. Hardness may be characterized into three basic categories, e.g., scratch test, rebound test, and indentation test. Among them indentation hardness test is widely used in which an indentation is impressed over the surface of the materials and hardness can be measured by the function of force and size. In an indentation hardness method, there are further different types of hardness tests such as macro hardness tests that includes Rockwell, Vickers and Brinell and micro hardness tests includes tukon and knoop [62]. Table 3 shows the improvement of hardness for different coating techniques and materials as well.

Substrate

Coating material

Process

Bath

Hardness (Hv)

Ref

ST37 steels

Ni-Al

Electrodeposition

watt's bath

Ni=280

[63]

Copper

Ni

Electrodeposition

watt's bath

Ni=300

[7]

mild steel

Ni

Electrodeposition

watt's bath

Ni=240

[64]

Al alloy

Ni

Electrodeposition

watt's bath

Ni=230

[65]

CYT15 cemented carbide

CrN

Cathode arc-evaporation technique

-

CrN=1628

[66]

AISI 4140 alloy steel

Cr, CrN. CrN/Cr

ED and PVD

-

Cr (ED)=832

CrN(PVD)= 2128[67]

Table 3: Coating hardness of electrodeposition and PVD samples.

ii. Surface Roughness

Surface roughens is related to the texture of the surface, that how it exists and it effects greatly on mechanical properties. There are many factors concerned with surface roughness such as surface topography, irregularities, smoothness, scratches, cracks, wear, co-efficient of friction and etc. [68]. Surface roughness on the one hand is not good for materials/ coatings as it increases irregularities and roughness that leads to the destruction of materials and on the other hand it is good for coating as it increases adhesion of coating to the substrate but that should be in limited range [69]. There are different techniques to measure surface roughness of the coatings or materials just like, profilometry (stylus, optical), atomic force microscopy, and etc. [70]. There are various parameters used for measuring surface roughness that are shown in Table 4. Table 5 shows the changes of surface roughness for different coating techniques and materials as well.

Roughness parameter

Description

Ra

Average roughness

Rz

Mean peak-to-valley height

Ry

Total roughness height

Rp

Maximum peak height

Rt

Total peak-to-valley height

Rq

Root-mean-square (RMS) profile height

Rv

Valley depth

Rmax

Maximum peak-to-valley height

Rpm

Mean peak height

R3z

Mean third highest peak-to-valley height

Rku

Kurtosis of the assessed profile

Rsk

Skewness of the assessed profile

Rvm

Maximum valley depth

R3zmax

Maximum third highest peak-to-valley height

Table 4: Roughness parameters [68,70-72].

Substrate

Coating material

Process

Bath

Roughness Ra (nm)

Ref

ST37 steels

Ni-Al

Electrodeposition

watt's bath

170

[63]

Copper

Ni

Electrodeposition

watt's bath

38

[7]

YT15 cemented carbide

CrN

Cathode arc-evaporation technique

-

1780

[66]

Stainless steel

Cr

Reactive pulsed DC magnetron

sputtering-

10 to 25

[73]

Silicon wafer

CrN

Pulsed DC magnetron sputtering

-

2 to 8

[74]

Table 5: Changes of coated surface roughness for different coating techniques and materials.

iii. Adhesion strength

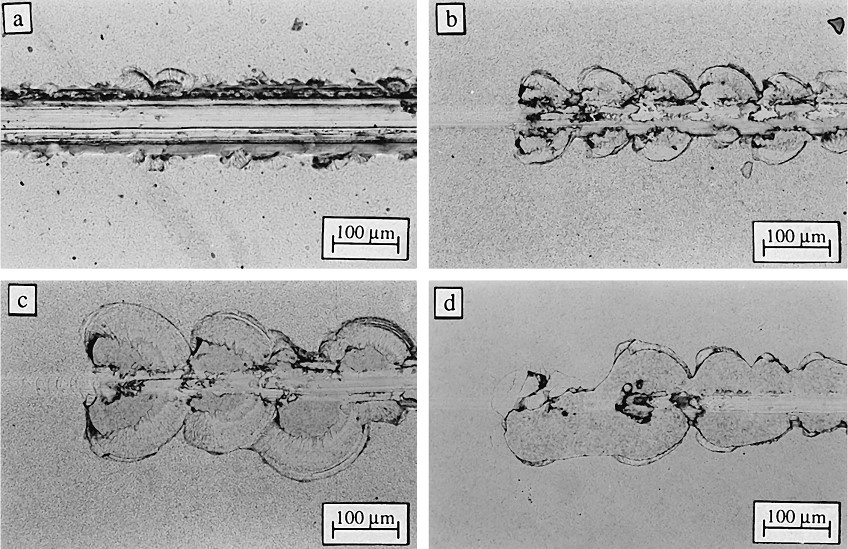

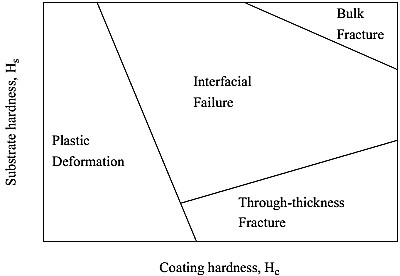

In surface engineering where coatings are involved, adhesion play very important role in between substrate-coating. In general, adhesion means interaction in between coating and substrate and bond between them is the most important factor to consider. Adhesion is very important to be considered for assessing the quality, performance and durability of a coating, as once the coating is delaminated or spallation take place, the substrate will directly be exposed to the environment that will deteriorate the substrate in very short time [24,75]. In many cases different methods are being used for pretreatment of the coating sample, such as brushing, micro-blasting, water peening and etc., are applied to increase adhesion in between coating to substrate [25]. Adhesion test normally carried out by simply drawing an indenter to form scratch over the coating staring from zero as an initial load, which is then gradually increased by some force with certain velocity. The micro scratch indented over the coating is then observed through optical microscope. Generally there are 3-4 steps to measure the coating/substrate adhesion, i-e; elastic to plastic transition or crack initiation, chipping (LC1), adhesive failure or spallation (LC2), and total failure (LC3) [76]. For measuring adhesion there are various methods just like scratch adhesion test, impact adhesion test, Rockwell-C adhesion test [77]. Figure 4 shows the different coating failures encountered: (a) Minor cohesive failures / elastic to plastic transition or crack initiation (b) minor semicircular cracks at critical load / chipping (LC1) (c) large semi-circular cracks at critic load/adhesive failure or spallation (LC2) (d) and substrate exposure/ total failure (LC3) [78]. The graphical picture of the main scratch test failure modes in terms of coating-substrate hardness (Hc and Hs, respectively) is shown in Figure 5.

Figure 4: Representation of the modes of coating failure (a) Small cohesive failures/ elastic to plastic transition or crack initiation (b) small semicircular cracks at critical load/chipping (LC1) (c) large semi-circular cracks at critic load/ spallation (LC2) (d) and substrate exposure/ total failure (LC3) [78].

Figure 5: Graphical picture of the common modes of scratch test failure modes in terms of coating and substrate hardness (Hc and Hs, respectively [76,79].

iv. Friction and Co-efficient of Friction

Theoretically friction may be defined as the force resisting the relative motion of materials sliding against each other. Friction is believed to be a significant mechanical property in an automotive industry. Practically when two bodies are moving in contact, relative to each other, the kinetic friction is generated and can be determined by using Equation 2.1.

V.

Where fk is the frictional resistive force, μk is kinetic friction coefficient and P is the normal applied load. From the measured friction values, we can get the coefficient of friction using Equation 2.2.

vi.

Coefficient of friction is represented with Greek letter μ that defines the relation of the frictional resistive force between two bodies and the normal load pressing them together. Friction and COF are related to the roughness interaction of the surface and adhesion between coating-substrate, so as the degree of roughness increases, the value of friction coefficient also increases [72]. There are many kinds of friction, just like, fluid friction, dry friction, internal friction etc. and the methods extensively used to measure friction and COF are micro scratch testing and tribometer. Friction coefficients could also be varied depending on the types of materials couples. Table 6 shows the friction coefficients for different types of materials.

Materials

Friction coefficients

Metal–metal in vacuum (< 10-7 Pa)

>3

Meta l–metal in air

0.2 to 1.5

Polymer–polymer in air

0.05 to 1

Metal–polymer in air

0.05 to 0.5

Metal–ceramic or ceramic–ceramic in air

0.2 to 0.5

Metal–metal with solid lubricant (PTFE, MoS2, graphite)

0.05 to 1

Metal–metal with oil lubricant (outside hydrodynamic regime)

0.1 to 0.2

Lubrication in the hydrodynamic regime

0.001 to 0.005

Table 6: Friction coefficients for different couples of materials [80].

Corrosion control through coatings: Corrosion control is one of the important purposes of applying coating. However selection of the best corrosion control coating should meet both technical requirements and economical factors. The major technical criteria when opting for an anti-corrosion layer could be i) corrosion mitigation, ii) thermal stability, iii) chemical stability and Robustness of the topcoats ( toughness and hardness). On the other hand, the economic factors when opting for an anti-corrosion layerbcould be i) service life enhancement, ii) Readiness with minimum preparation iii) Reduced number of coats, iv) Fast return to service (fast dry), v) Fast throughput. Minimum maintenance requirement leads to lower lifetime cost. The significance of technical parameters and financialfactors when opting foring an anti-corrosive layer is shown in Table 7.

Criteria

Factors

Improtance (%)

Technical factors

i) corrosion control

~ 98

ii) Thermal stability

~ 88

iii) chemical stability

~ 87

iv) Topcoat robustness (Toughness and hardness)

~ 87

Economical factors

i) Long service life

~ 97

ii) Surface tolerance / low preparation

~ 91

iii) Minimum number of coats

~ 82

iv) Fast return to service (fast dry)

~ 82

v) Fast throughput

~ 72

Table 7: Significance of technical parameters and financial factors when opting for an anti-corrosive layer [81].

Decorative and Functional properties: The purpose of applying the coating could also be decorative, functional, or both. It is worth noted that the surface coatings play an important role to enhance the surface properties of any materials for a particular application. If any material examined under a microscope, a rough or dull surface finish shows an uneven surface, for which most of the waxing and polishing process are introduced to make the surface shinny by smoothing the roughness. This is because a dull surface scatter the light coming from a source and it reflect back in a non-parallel and random direction that blurred the surface. In contrary, a smooth and flat surface reflects the light in a parallel and even direction- just like a mirror that shows a shinning surface finish. The foremost ares where these properties are applicable are reflectors/absorbers/emitters, forming and cutting tools, micro-electronic and information storage devices, sensors, solar devices coatings and environment-resistant protective or decorative coatings. Hence surface coatings play all the time an important role to the present and upcoming era of industrial technoligy and upcoming era of industrial technoligy.

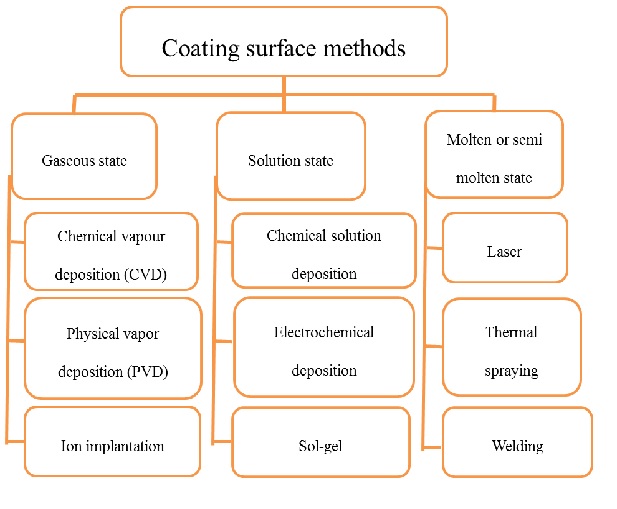

General Coating Techniques

There is wide range of categories for surface treatment, which modify and enhances the life, compatibility, and overall performance of the surface of the material for better performance. In engineering, generally the term deposition is used for coatings. Coating techniques are mainly classified in three states of deposition conditions, that are gaseous state, solution state and molten/semi molten state [82]. Moreover, the primary important deposition techniques used in these categories are given in Figure 6.

Figure 6: General coating techniques.

Electrodeposition: Electrodeposition is primarily employed for its faster deposition rate, flexibility, strong adhesion, flexibility, compositional and parametric control and cost effectiveness [4,8,50,63,86-88]. It is used for many applications and in many environments. Some of the electrodeposited coatings with different substrate and coating materials are in Table 8, that enhances mechanical and chemical properties in various applications.

Substrate materials

Coating materials

Findings

References

Steel

Nickel,

Nickel and Tungsten AlloysCorrosion resistance ↑, oxidation stability ↑, mechanical integrity ↑

[50]

Steel

Nickel–Aluminum

Corrosion resistance ↑, Hardness ↑

[63]

Mild steel

Nickel, Nickel-Tungsten Carbide

Microhardness ↑, tribological ↑

[64]

Nickel plates

Nickel-Chromium

Oxidation resistance ↑

[87]

Copper

Titania particles in a

nickel matrixMicrohardness ↑, wear resistance ↑

[8]

Copper

Nickel

Corrosion resistance ↑, Hardness ↑, roughness ↑

[7]

Table 8: Chemical and mechanical properties of electrodeposited coatings.

Electrodeposition process is one of the types of electrochemical process that is widely being used for automotive applications. As it is a solution state base deposition so here chemical reactions take place to form coatings. Chemical reactions take place by adding different chemicals in a diluted water to form solution. There are different types of solution baths for different applications, depends upon the particular properties, environmental conditions and requirements. Electrochemical solution baths are varied by varying the chemicals, their particular concentrations and varying operating parameters and conditions. Some of the electrodeposition baths are Watts’s bath, Nickel sulfamate bath, sulfate-chloride bath and etc. Amongst them the mostly used bath is Watts’s electrolyte bath, having composition of Nickel sulphate (NiSO4) as a source of Nickel coating aggregates with Ni-chloride (NiCl2) as an anode activator and also boric acid is added as a buffering agent. Beside that sodium hydro-oxide (Na-OH) and Sulfuric acid (H2SO4) are used to retain the pH-value persistent at 3–4. The average current density kept below 5000 mA/dm² [25].

Electrodeposition process have many important properties just like, increase corrosion resistance, tribological properties like friction, and wear and also exhibits better surface finishing. And approximately 40% electroplated products are utilized in an automotive industry, mainly for resistance to corrosion [25]. Chemical (including composition) and physical characteristics of the electrodeposited coatings are altered using deposition parameters (Agitation, current density, temperature and applied current) along with the bath chemistry [8,83]. Most commonly used materials for electrodeposition are nickel, zinc, chromium, tungsten and etc. During electroplating the metallic ions are deposited over the substrate material from the solution and working electrode, usually following reaction take place in electrodeposition:

At cathode Mz+ (aq) + ze- M(s)

At anode M(s) Mz+ (aq) + ze-

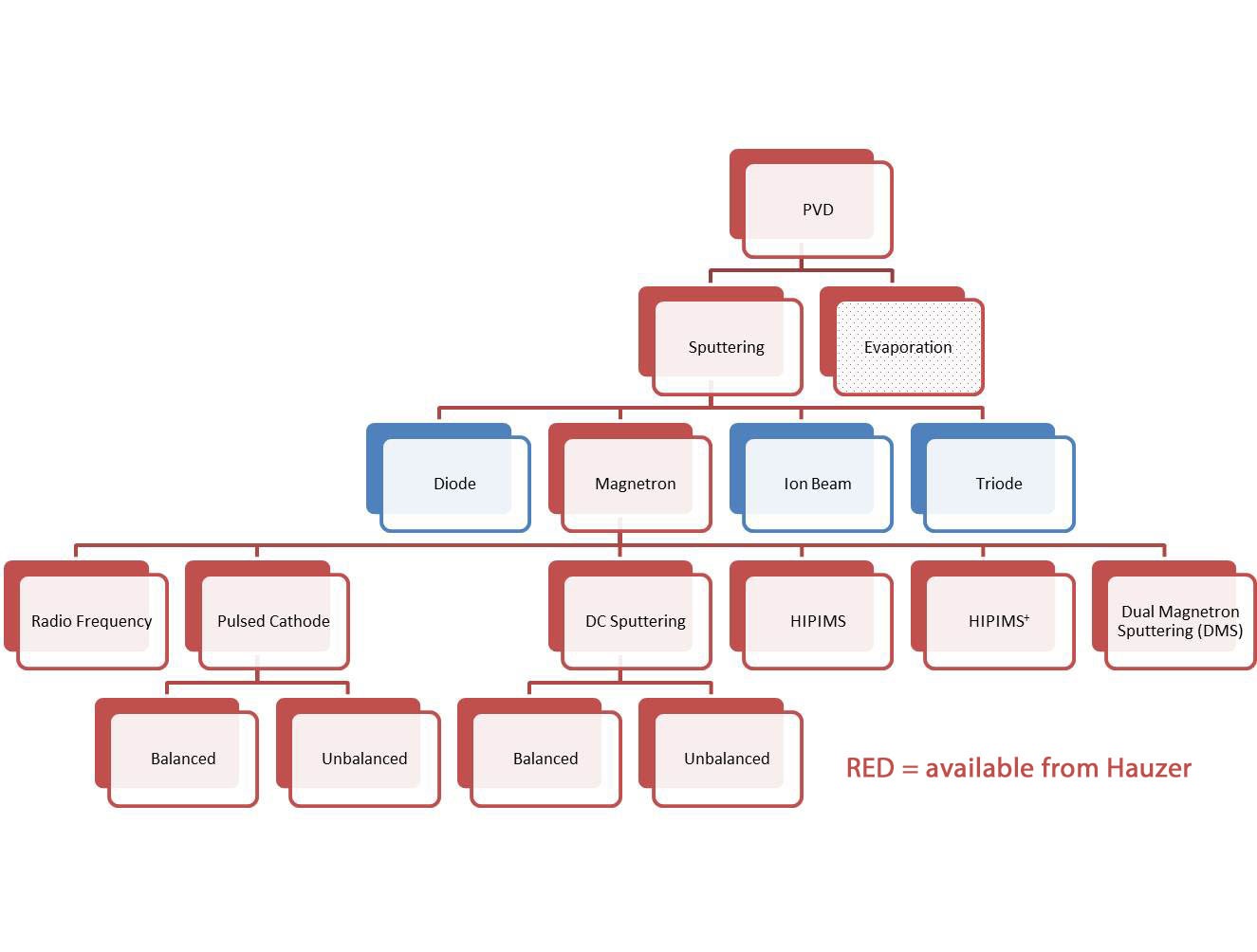

Magnetron sputtering: PVD is a gaseous state coating technique where deposition of coating takes place by atomizing and formation of vapors from a solid target metal and thereby deposition of the subjected material on to the base metal or substrate to form a coating. Mainly PVD is divided into evaporation and sputtering that works in a vacuum chamber. The main PVD coating techniques are enlisted in Figure 7.

Figure 7: Different PVD techniques [89].

Furthermore, magnetron sputtering offers improved compositional control, better adhesion, improved surface finish, higher crystallinity, enhanced rate and deposition possibility of depositing a wide variety of compounds in comparison to the sputtering [9,10,27,90,91]. Moreover, magnetron sputtering coatings provides good mechanical (high wear resistance, appearance, low friction, etc.) and corrosion properties [6,13,25,92-98]. Some of the physical vapor deposition coatings with different substrate and coating materials are given in Table 9. That enhances mechanical and chemical properties in various applications.

Substrate materials

Coating materials

Findings

References

Aluminium alloys

CrN and Ni/CrN

Corrosion resistance ↑, Hardness ↑

[99]

Steel

TiAlN and TiAlSiN

Oxidation resistance ↑, Hardness ↑, adhesion ↑

[100]

Stainless steel

Ti, AlN

Microhardness ↑, friction and wear ↑

[101]

Stainless steel

ZrOxNy/ZrO2

Corrosion resistance ↑

[102]

Steel

Ti–B–C

Tribo-mechanical ↑, Corrosion resistance ↑

[103]

Steel

CrSiCN

Mechanical and tribological ↑

[104]

Note: Arrow ↑shows increase in properties

Table 9: Chemical and mechanical properties of physical vapor deposition coatings.

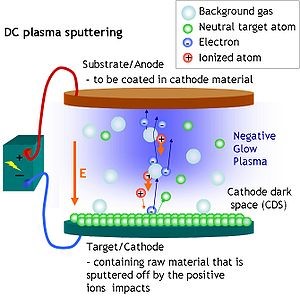

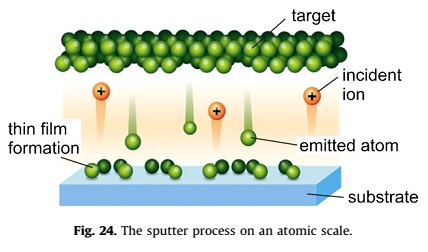

Metal oxides, carbides and nitrides can be deposited by introducing the desired gas inside the magnetron sputtering chamber. This technique is known as reactive magnetron sputtering. Though, it is very slow process having deposition rates in the range of nm/s, but in comparison with electrodeposition and other deposition process the sputtering particles has much higher energy than the evaporated particles energy so that the developed layer exhibits better physical characteristics [25,105]. Figure 8 depicts the atomic process that occurs during the PVD coating.

Figure 8: Physical vapor deposition sputtering process.

Generally sputtering may be known as ‘‘billiard game with ions and atoms’’. Wherein +ve ions are produced in a plasma state that are generated in between sputtering target (cathode) and substrate material (anode). Usually, argon is used as a sputtering gas so as to carry the ionic particles in a direction from cathode to anode and also to increase the rate of reaction without substantially loss of energy. Before deposition of coating, vacuum chamber is evacuated as much as possible to avoid any of the contamination with foreign particles.

In sputtering electric current is applied that creates electric field in between anode and cathode, thereby strike with sputtering target surface and transmit their energy to the sputtering target (cathode) that emits its atoms in the direction of substrate material (anode) and form a thin coating over the substrate material (Figure 9).

Figure 9: The sputter process on an atomic scale [25].

The variety of coating materials deposited can be immense in terms of compounds formation. The main benefits of magnetron sputtering are:

i. Very minimal plasma impedance allowing to release increased current in the definite range (1–100) Amperes current (this property is dependent on target length) at almost 500

ii. The deposition rates, ranges from 1 nanometer per second to 10 nanometers per second and can be viable for mass production.

iii. It may deposit thin films over the thermal sensitive materials due to having less thermal load on the material.

iv. Coating quality in terms of homogeneity and diffusion is excellent even for the cathodic lengths up to meters.

v. Good film adherence and density.

Coating Materials

Globally various groups of people are focusing to enhance the mechanical and tribological characteristics of automobile parts by different materials. So to enhance the coating characteristics, selection of coating materials is a crucial task.

Selection of Coating materials

Materials do not usually provide satisfactory performance against multidimensional functionalities, for such applications materials synergistic properties are utilized. This synergistic approach has resulted in the exploration of a variety of materials and processing techniques to deposit different layers of coatings. Such coatings act as a barrier against surface degradation or corrosive degradation [13,25]. Selection of a coating material is therefore very important to meet the desired demand. Coating materials do have corrosion resistance, tribological properties, economical, long-term durability, good adhesion to substrate, hardness, and it must have much more properties required for automotive application. Usually, automotive industry used coating materials just like Ni, Cr, Ti, Al, transition nitride coatings [9,12-14].

Nickel: Nickel has received highest interest as a result of its attractive set of tribological and magnetic characteristics [7,16,17]. For this purpose, Ni electroplating is more convenient technique [18] that is being studied since years [7,106,107]. Ni can be deposited on commercial scale by electrodeposition on batch level [108] with respect to compatibility and economically [7,19,109], and its enormous characteristics and control mechanism of watt’s bath [7].

Chromium: CrN is also considered as one of the best material used for coatings in automobile industries [25,110,111]. CrN are known as hard coatings that shows greater hardness and toughness, well fatigue and wear properties, lower frictional coefficient, having good thermal stability and can also withstand in oxidative and corrosive environment [19-22] and also exhibits good surface finish [25-28]. Indeed Cr has a wide range of applications but it has a limitation to be deposited via electrodeposition due to toxic in nature. Most common technique used for Cr deposition is PVD technique to form thick / thin CrN coatings. Besides that, porosity and pinholes are also generated during electroplating that further propagates to from cracks and generated the path for corrosion [9,26,110,112,113].

Nitrogen: Nonetheless, apart from Ni and Cr, nitrogen is also an essential coating material that can be deposited through nitriding in the form of plasma nitriding. Nitriding greatly enhance the performance of automotive components [114]. Plasma nitriding enhances surface fatigue strength, hardness, creates residual stresses, and much more properties. Nevertheless, combining effect of nitriding and PVD make it possible to form much better coating products that could be formed individually. They possess much better tribological properties [13]. Additionally, PVD sputtering can also change the structural phases (like CrN and Cr2N) by just sputtering the nitrogen and monitoring its flow rate in vacuum environment [29]. It can also control phase stability and the environmental factors efficiently [26,115-118]. Moreover, it shows better properties (such as wear, oxidation and corrosion) than TiN [49,119-121].

Combinative Coatings: Nickel, chromium and nitrogen as an individual, play their respective vigorous role, as much of their properties are already been discussed above. However, if we combine all of these coatings in a bilayer, ternary or in a gradient layer, they form much better properties, superior to single coatings and may be termed as combinatorial formations of layers. Many researches worked on combinatorial effect of CrN, Ni-Cr, and NiCrN coatings through different techniques and found better improvement in overall coating properties [15,24,122-124].

Combinatorial is the methodology of finding and studying new materials that combines different chemical mixture and provides enough output data within a short time that can be investigated to change huge numbers of advanced materials by simply changing the compositions [125]. Principally combinatorial means to form two or more than to two elements in various proportions, and each property of the resulting combinations are assessed to identify those with unique or desirable characteristics. So here we intended to form combinatorial CrNiN coatings through magnetron sputtering and electrodeposition in different ways. Reason to go for combinatorial coatings is to measure the structural and mechanical properties of surface coatings.

Coating Layers

As mentioned before, CrNiN transition elements are used to form different layer(s) formation. Firstly, Ni single layer coating is formed through electrodeposition, secondly CrNiN ternary single layer formed through magnetron sputtering, thirdly CrNiN ternary gradient layers formed through magnetron sputtering, and finally Ni single layer deposited with CrN bilayer coatings.

Single layer Coating: Single layer electrodeposited and PVD coatings are commonly employed numerous applications including, automotive applications, decorative, biomedical, cutting tools etc. providing better corrosion resistance and wear performance [21]. These coatings are easy to develop without thinking of phase formation with other elements. However, trend is shifting towards multilayer coatings as they can offer unique sets of properties [55].

Bilayer Coatings: Among all monolithic materials, nickel is considered as a widely used anti-corrosive, economical and softer material [7]. On the other hand, transitional bilayer metallic coatings like ZrN, NiN, CrN, TiN etc. improved the applications for various materials. Moreover, among these transitional nitride base coatings, CrN owe better properties like thermal stability at higher temperatures, wear resistance and good hardness [112]. Nevertheless, single layer coating exhibits inadequate properties with respect to combinatorial coatings. So by combining the softer Ni phase with harder CrN phase provides greater fracture toughness in the form of ternary coating system [126,127]. Indeed, hybrid coating system having one harder and one tougher phase are supposed to be promising coatings that can withstand any catastrophic failure [25].

Bilayers coatings are supposed to have minimal defects with greater resistance to crack formation, exhibits greater mechanical characteristics like wear resistance, greater hardness less friction, and it also compensate the stresses formed internally during the deposition process [128,129]. Though, wide range of research has been done on NiCrN coatings using various techniques [19,130]. So, combining hard CrN coatings with softer Ni coatings deposited via PVD and electroplating techniques respectively are considered to be most viable techniques to resolve many problems like internal stresses, cracks along with better adhesion [24,110]. Combinatorial coating techniques were also used by different other researchers in different ways for different applications [13,28,62,131,132].

Gradient layer Coatings: Single, bilayer and multi layers have their respective importance and when it comes for gradient layers it has much better advantages. As single layer coatings have very limited applications as compared to bilayer, whereas bilayer again has limited usefulness then multilayers for catrostrophic environments. However multilayer coatings have significantly more importance than single and bilayer, as they exhibits significantly more tribological and chemical properties [98,133].

But as multilayers have definite coating thickness with different and distinctive boundaries among the coatings, so in this sense gradient layers have some more exceptional properties and are considered as a mixture of unlimited multilayer coatings without distinctive boundaries [134]. For this reason, gradient coating layers have much better and almost stable mechanical properties [135,136].

Nowadays research and investigation is being carried out to deposit combinatorial gradient coatings by controlling particles distribution and composition of the coatings [61]. Inadequate research attention has been devoted for the development of Chromium and Nickel phases together. Until now the predominantly employed technique for the development of CrNiN for safety components, magnetic layers and cutting tools is closed field unbalanced magnetron sputtering [36,37,38].

Multilayer coatings can significantly improve substrate adhesion and resist the formation of surface defects such as, craters, cracks and pinholes [3,137]. Until now, there is unavailability of the comparative analysis of the mechanical performance of the single layer versus ternary gradient layer coatings in (Cr, Ni) N system.

Summary and Conclusions

In automotive industry, different types of materials are used to prepare different components. The used materials possess different properties. In modern technology, the inherent properties of materials cannot meet all the requirements related to their mechanical, chemical, optical, tribological, corrosion resistance, decorative and functional properties. Therefore, application of coating is found to be an important way to improve the surface properties of materials. In the present literature study, mild steel is found to exhibit few drawback properties. Those are, corrosion and diminishing in tribological properties due to longer periods of time. So, to overcome these drawbacks coating is found to be necessary, that modify surface properties of the material. There is a wide range of categories for surface coating that improve the strength, compatibility, life and many other properties of the materials. Coating technology such as magnetron sputtering and electrodeposition could address the concerns at satisfactory level that are widely being used for many of the automotive applications.

Electrodeposition technique is widely being used for its higher and controllable deposition rate, intricate shapes are also coated and the better concerning factor is that it is more economical. In electrodeposition, chemical process take place in a solution of dilute water. Electrodeposition coating enhances corrosion resistance, tribological properties and gives better outlook. Coating thickness, composition, and many other properties of the coating are easy to be control by its parameters.

Whereas physical vapor deposition also has much better properties in which solid atoms are ionized in form of vapors that are deposited over the substrate to form coatings. In physical vapor deposition, magnetron sputtering gives better surface finishing, control coating composition, form much better adhesion with substrate, very less impurity due to vacuum environment, and have much more other properties.

Besides coating techniques, coating materials are also very essential for any of the coatings. There is wide range of coating materials that are used for different automotive applications and for different environmental conditions. There are many factors that are to be considered for better coating, such as hardness, stiffness, long term durability, adhesion to substrate, coefficient of friction, and many others. Mostly used industrial coating materials are Ti, Al, Ni, Cr, Co, transitional nitride and etc. Here in this research, we choose Ni, Cr and Nitride coatings due to wide range of advantages, the most important is combination of Ni soft and CrN hard coatings that can sustain thermal and sudden shocks, resistance to corrosion, and enhance tribological properties. After coating technique and coating material, formation of coating layers is also an important factor to consider. Single layer, bilayer, and gradient coating layers are used for different applications that depend on many factors, such as environmental condition, usage, sustainability, economy and etc. Single layer coating is easy to form and is also economical, depends upon coating technique and coating materials, but it has limited applications. Whereas bilayer and gradient layers are somehow difficult to form, as more than one layer is formed with same or may be with different coating technique and coating materials. But bilayer and gradient coating layers have much better properties and wide applications as compare to single coating layer. This is because bilayer and gradient layer have combination of coating technique and materials that can compensate many automotive applications.

Author Statements

Acknowledgment

Author thanks to department of Metallurgical Engineering NED UET Karachi for their support.

References

- Bhatti J, Fazal MA, Bushroa AR, Khan AF, Quazi MM. Structural and mechanical properties of (Cr, Ni) N single and gradient layer coatings deposited on mild steel by magnetron sputtering. Tribol Mater Surf Interfaces. 2016; 10: 117-25.

- Vinodhini SP, Xavier JR. Evaluation of corrosion protection performance and mechanical properties of epoxy-triazole/graphene oxide nanocomposite coatings on mild steel. J Mater Sci. 2021; 56: 7094-110.

- Chen Z, Zhou K, Lu X, Lam YC. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014; 225: 431-52.

- Fayyaz O, Khan A, Shakoor RA, Hasan A, Yusuf MM, Montemor MF, et al. Enhancement of mechanical and corrosion resistance properties of electrodeposited Ni–P–TiC composite coatings. Sci Rep. 2021; 11: 5327.

- Padamata SK, Yasinskiy A, Yanov V, Saevarsdottir G. Magnetron sputtering high-entropy alloy coatings: A mini-review. Metals. 2022; 12: 319.

- Chipatecua YL, Olaya JJ, Arias DF. Corrosion behaviour of CrN/Cr multilayers on stainless steel deposited by unbalanced magnetron sputtering. Vacuum. 2012; 86: 1393-401.

- Nasirpouri F, Sanaeian MR, Samardak AS, Sukovatitsina EV, Ognev AV, Chebotkevich LA, et al. An investigation on the effect of surface morphology and crystalline texture on corrosion behavior, structural and magnetic properties of electrodeposited nanocrystalline nickel films. Appl Surf Sci. 2014; 292: 795-805.

- Thiemig D, Bund A. Characterization of electrodeposited Ni–TiO2 nanocomposite coatings. Surf Coat Technol. 2008; 202: 2976-84.

- Baptista A, Pinto G, Silva FJG, Ferreira AA, Pinto AG, Sousa VFC. Wear characterization of chromium PVD coatings on polymeric substrate for automotive optical components. Coatings. 2021; 11: 555.

- Wu F-B, Duh J-G. Mechanical characterization of Ni–P-based ternary coatings by RF magnetron sputtering. Thin Solid Films. 2003; 441: 165-71.

- Subramanian B, Jayachandran M. Characterization of reactive magnetron sputtered nanocrystalline titanium nitride (TiN) thin films with brush plated Ni interlayer. J Appl Electrochem. 2007; 37: 1069-75.

- Creus J, Idrissi H, Mazille H, Sanchette F, Jacquot P. Improvement of the corrosion resistance of CrN coated steel by an interlayer. Surf Coat Technol. 1998; 107: 183-90.

- Vetter J, Barbezat G, Crummenauer J, Avissar J. Surface treatment selections for automotive applications. Surf Coat Technol. 2005; 200: 1962-8.

- Pawlowski L. The science and engineering of thermal spray coatings. John Wiley & Sons; 2008.

- Tareen AK, Priyanga GS, Behara S, Thomas T, Yang M. Mixed ternary transition metal nitrides: A comprehensive review of synthesis, electronic structure, and properties of engineering relevance. Prog Solid State Chem. 2019; 53: 1-26.

- Aus MJ, Szpunar B, El-Sherik AM, Erb U, Palumbo G, Aust KT. Magnetic properties of bulk nanocrystalline nickel. Scr Metall Mater. 1992; 27: 1639-43.

- Ul-Hamid A, Dafalla H, Quddus A, Saricimen H, Al-Hadhrami LM. Microstructure and surface mechanical properties of pulse electrodeposited nickel. Appl Surf Sci. 2011; 257: 9251-9.

- Nasirpouri F, Janjan SM, Peighambari SM, Hosseini MG, Akbari A, Samardak AS. Refinement of electrodeposition mechanism for fabrication of thin nickel films on n-type silicon (111). J Electroanal Chem. 2013; 690: 136-43.

- Zhang ZG, Rapaud O, Allain N, Mercs D, Brien V, Dong C, et al. Influence of Ni content on the structure and properties of Cr–Ni–N coatings prepared by direct current magnetron sputtering. Thin Solid Films. 2009; 517: 3304-9.

- Wu F-B, Chen Y, Peng P, Tsai Y, Duh J. Fabrication, thermal stability and microhardness of sputtered Ni–P–W coating. Surf Coat Technol. 2002; 150: 232-8.

- Chipatecua YL, Olaya JJ, Arias DF. Corrosion behaviour of CrN/Cr multilayers on stainless steel deposited by unbalanced magnetron sputtering. Vacuum. 2012; 86: 1393-401.

- Cheng WL, Zhou ZF, Shum PW, Li KY. Effect of Ni addition on the structure and properties of Cr–Ni–N coatings deposited by closed-field unbalanced magnetron sputtering ion plating. Surf Coat Technol. 2013; 229: 84-9.

- Su YL, Yao SH, Leu ZL, Wei CS, Wu CT. Comparison of tribological behavior of three films—TiN, TiCN and CrN—grown by physical vapor deposition. Wear. 1997; 213: 165-74.

- Al-Asadi MM, Al-Tameemi HA. A review of tribological properties and deposition methods for selected hard protective coatings. Tribol Int. 2022; 176: 107919.

- Bewilogua K, Bräuer G, Dietz A, Gäbler J, Goch G, Karpuschewski B, et al. Surface technology for automotive engineering. CIRP Ann Manuf Technol. 2009; 58: 608-27.

- Kot M, Rakowski WA, Major L, Major R, Morgiel J. Effect of bilayer period on properties of Cr/CrN multilayer coatings produced by laser ablation. Surf Coat Technol. 2008; 202: 3501-6.

- Engel P, Schwarz G, Wolf GK. Corrosion and mechanical studies of chromium nitride films prepared by ion-beam-assisted deposition. Surf Coat Technol. 1998; 98: 1002-7.

- Chen J-S, Duh J-G, Wu F-B. Microhardness and corrosion behavior in CrN/electroless Ni/mild steel complex coating. Surf Coat Technol. 2002; 150: 239-45.

- Barata A, Cunha L, Moura C. Characterisation of chromium nitride films produced by PVD techniques. Thin Solid Films. 2001; 398-399: 501-6.

- Lee S, Choi M, Park S, Jung H, Yoo B. Mechanical properties of electrodeposited Ni-W ThinFilms with alternate W-rich and W-poor multilayers. Electrochim Acta. 2015; 153: 225-31.

- Fella R, Holleck H, Schulz H. Preparation and properties of WC-TiC-TiN gradient coatings. Surf Coat Technol. 1988; 36: 257-64.

- Voevodin AA, Capano MA, Laube SJP, Donley MS, Zabinski JS. Design of a Ti/TiC/DLC functionally gradient coating based on studies of structural transitions in Ti–C thin films. Thin Solid Films. 1997; 298: 107-15.

- Aliofkhazraei M, Rouhaghdam AS. Fabrication of functionally gradient nanocomposite coatings by plasma electrolytic oxidation based on variable duty cycle. Appl Surf Sci. 2012; 258: 2093-7.

- Kuo KH, Lee J, Chen S, Chien FL, Lee R, Lau J. Electromigration performance of printed Sn0.7Cu bumps with immersion tin surface finishing for flip chip applications 62nd Electronic Components and Technology Conference (Ectc). Ieee Publications. 2012; 2012: 698-702.

- Lackner J, Waldhauser W, Major L, Kot M. Tribology and micromechanics of chromium nitride based multilayer coatings on soft and hard substrates. Coatings. 2014; 4: 121-38.

- Wo PC, Munroe PR, Jiang Z, Zhou Z, Li KY, Xie Z. Enhancing toughness of CrN coatings by Ni addition for safety-critical applications. Mater Sci Eng A. 2014; 596: 264-74.

- Okumura Y, Yasui M, Akita T, Maeda M, Yang XB, Fujimori H. Effects of CrNiN pre-layer on magnetic properties and medium noise of CoCrTa longitudinal media. J Magn Magn Mater. 1998; 185: 249-57.

- Zhang ZG, Rapaud O, Allain N, Mercs D, Brien V, Dong C, et al. Influence of Ni content on the structure and properties of Cr–Ni–N coatings prepared by direct current magnetron sputtering. Thin Solid Films. 2009; 517: 3304-9.

- Sant T. Material selection – an important aspect of vehicle engineering; 2013.

- Beake BD, Ranganathan N. An investigation of the nanoindentation and Nano/micro-tribological behaviour of monolayer, bilayer and trilayer coatings on cemented carbide. Mater Sci Eng A. 2006; 423: 46-51.

- Forum, I.s.s. automotive applications. Available from: http://www.worldstainless.org/transport_applications/automotive_applications. Outokumpu; 2012.

- Edgar J. Steel identification using hardness testing. (Available from: http://www.autospeed.com/cms/title_Steel-Identification-Using-Hardness-Testing/A_109717/article.html. 2008; 462.

- GUPTA J. MECHANICAL AND WEAR PROPERTIES OF CARBURIZED MILD steel SAMPLES in mechanical engineering. Rourkela, India: National Institute of Technology. 2009; 69.

- Cursaru D-L, Branoiu G, Ramadan I, Miculescu F. Degradation of automotive materials upon exposure to sunflower biodiesel. Ind Crops Prod. 2014; 54: 149-58.

- Fazal MA, Jakeria MR, Haseeb ASMA. Effect of copper and mild steel on the stability of palm biodiesel properties: A comparative study. Ind Crops Prod. 2014; 58: 8-14.

- Fourlaris G, Ellwood R, Jones TB. The reliability of test results from simple test samples in predicting the fatigue performance of automotive components. Mater Des. 2007; 28: 1198-210.

- Cao R, Huang Q, Chen JH, Wang P. Cold metal transfer spot plug welding of AA6061-T6-to-galvanized steel for automotive applications. J Alloys Compd. 2014; 585: 622-32.

- Zhang Y, Lai X, Zhu P, Wang W. Lightweight design of automobile component using high strength steel based on dent resistance. Mater Des. 2006; 27: 64-8.

- Wu F-B, Li J-J, Duh J-G. Evaluation of the mechanical properties and tribological behavior of the CrN coating deposited on mild steel modified with electroless Ni interlayer. Thin Solid Films. 2000; 377-378: 354-9.

- Boonyongmaneerat Y, Sukjamsri C, Sahapatsombut U, Saenapitak S, Sukkasi S. Investigation of electrodeposited Ni-based coatings for biodiesel storage. Appl Energy. 2011; 88: 909-13.

- Makhlouf ASH. Protective coatings for automotive, aerospace and military applications: current prospects and future trends. In: Makhlouf ASH, editor. Handbook of smart coatings for materials protection. Woodhead Publishing. 2014; 121-31.

- Mutafov P, Evaristo M, Cavaleiro A, Polcar T. Structure, mechanical and tribological properties of self-lubricant W–S–N coatings. Surf Coat Technol. 2015; 261: 7-14.

- Lepule ML, et al. Corrosion and wear behaviour of ZrO2 modified NiTi coatings on AISI 316 stainless steel. Surf Coat Technol. 2015; 261: 21-7.

- Mohseni M, Yari H, Ramezanzadeh B. The current status of automotive coatings and future trends using nanotechnology.

- Vetters HR, Schulz A, Mayr P, Saunders SRJ. Characterization and properties of hard coatings; international standardization efforts. Surf Coat Technol. 1996; 86-87: 345-50.

- Lee TH, Oh CS, Han HN, Lee CG, Kim SJ, Takaki S. On the crystal structure of Cr2N precipitates in high-nitrogen austenitic stainless steel. Acta Crystallogr B. 2005; 61: 137-44.

- Kim S-J, Marquart T, Franzen H. Structure refinement for Cr< sub> 2 N. Journal of the Less Common Metals. 1990; 158: L9-L10.

- Hornbogen E. Overview no. 37. Acta Metall. 1984; 32: 615-27.

- Hintermann HE. Adhesion, friction and wear of thin hard coatings. Wear. 1984; 100: 381-97.

- Perry AJ. Scratch adhesion testing of hard coatings. Thin Solid Films. 1983; 107: 167-80.

- Low CTJ, Wills RGA, Walsh FC. Electrodeposition of composite coatings containing nanoparticles in a metal deposit. Surf Coat Technol. 2006; 201: 371-83.

- Frafjord JJ. Combinatorial design of nickel-chromium alloys by physical vapor deposition and electron beam welding. 2004.

- Daemi N, Mahboubi F, Alimadadi H. Effect of plasma nitriding on electrodeposited Ni–Al composite coating. Mater Des. 2011; 32: 971-5.

- Surender M, Basu B, Balasubramaniam R. Wear characterization of electrodeposited Ni–WC composite coatings. Tribol Int. 2004; 37: 743-9.

- Ul-Hamid A, Quddus A, Al-Yousef FK, Mohammed AI, Saricimen H, Al-Hadhrami LM. Microstructure and surface mechanical properties of electrodeposited Ni coating on Al 2014 alloy. Surf Coat Technol. 2010; 205: 2023-30.

- Deng J, Wu F, Lian Y, Xing Y, Li S. Erosion wear of CrN, TiN, CrAlN, and TiAlN PVD nitride coatings. Int J Refract Met Hard Mater. 2012; 35: 10-6.

- Han S, Lin JH, Tsai SH, Chung SC, Wang DY, Lu FH, et al. Corrosion and tribological studies of chromium nitride coated on steel with an interlayer of electroplated chromium. Surf Coat Technol. 2000; 133-134: 460-5.

- Nunez EE, Polycarpou AA. The effect of surface roughness on the transfer of polymer films under unlubricated testing conditions. Wear. 2015; 326-327: 74-83.

- Brown CA. Relating surface texture and adhesion with area-scale fractal analysis. 8.

- Marteau J, Bigerelle M, Mazeran P-E, Bouvier S. Relation between roughness and processing conditions of AISI 316L stainless steel treated by ultrasonic shot peening. Tribol Int. 2015; 82: 319-29.

- Talu S, Stach S, Lainovic T, Vilotic M, Blažic L, Alb SF, et al. Surface roughness and morphology of dental nanocomposites polished by four different procedures evaluated by a multifractal approach. Appl Surf Sci. 2015; 330: 20-9.

- Mohamad ME, Ibrahim IS, Abdullah R, Abd. Rahman AB, Kueh ABH, Usman J. Friction and cohesion coefficients of composite concrete-to-concrete bond. Cem Concr Compos. 2015; 56: 1-14.

- Elangovan T, Kuppusami P, Thirumurugesan R, Ganesan V, Mohandas E, Mangalaraj D. Nanostructured CrN thin films prepared by reactive pulsed DC magnetron sputtering. Mater Sci Eng B. 2010; 167: 17-25.

- Lee J-W, Tien S-K, Kuo Y-C. The effects of pulse frequency and substrate bias to the mechanical properties of CrN coatings deposited by pulsed DC magnetron sputtering. Thin Solid Films. 2006; 494: 161-7.

- Chen Z, Zhou K, Lu X, Lam YC. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014; 225: 431-52.

- Bull SJ. Failure mode maps in the thin film scratch adhesion test. Tribol Int. 1997; 30: 491-8.

- Heinke W, Leyland A, Matthews A, Berg G, Friedrich C, Broszeit E. Evaluation of PVD nitride coatings, using impact, scratch and Rockwell-C adhesion tests. Thin Solid Films. 1995; 270: 431-8.

- Nordin M, Larsson M, Hogmark S. Mechanical and tribological properties of multilayered PVD TiN/CrN. Wear. 1999; 232: 221-5.

- Bull SJ, Berasetegui EG. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol Interface Eng S. 2006; 51: 136-65.

- Takadoum J. Materials and surface engineering in tribology. 2007. Great Britai. Chippenham, Wiltshire: CPI Antony Rowe Ltd. 2007; 243.

- HEMPEL, PROTECTIVE COATINGS in the Oil & Gas, Power Generation and Infrastructure Industries. HEMPEL: The Hempel Group Head Offie Hempel A/S Lundtoftegaardsvej 91 2800 Kgs. Lyngby Denmark.

- Dahotre NB, Kadolkar P, Shah S. Refractory ceramic coatings: processes, systems and wettability/adhesion. Surf Interface Anal. 2001; 31: 659-72.

- Wang SC, Wei WCJ. Kinetics of electroplating process of nano-sized ceramic particle/Ni composite. Mater Chem Phys. 2003; 78: 574-80.

- Alig I, Tadjbach S, Krüger P, Oehler H, Lellinger D. Characterization of coating systems by scanning acoustic microscopy: debonding, blistering and surface topology. Prog Org Coat. 2009; 64: 112-9.

- Almeida FA, Sacramento J, Oliveira FJ, Silva RF. Micro- and nano-crystalline CVD diamond coated tools in the turning of EDM graphite. Surf Coat Technol. 2008; 203: 271-6.

- Lampke T, Wielage B, Dietrich D, Leopold A. Details of crystalline growth in co-deposited electroplated nickel films with hard (Nano)particles. Appl Surf Sci. 2006; 253: 2399-408.

- Dong Z, Peng X, Guan Y, Li L, Wang F. Optimization of composition and structure of electrodeposited Ni–Cr composites for increasing the oxidation resistance. Corros Sci. 2012; 62: 147-52.

- Bin Humam S, Gyawali G, Amanov A, Kim TH, Lee SW. Microstructure, interface, and nanostructured surface modifications to improve mechanical and tribological performance of electrodeposited Ni-W-TaC composite coating. Surf Coat Technol. 2021; 419: 127293.

- Hauzer PVD. Coating technology; I.H.T.C. B.V., Editor: Netherland.

- Chang YC, Duh JG, Chen YI. Fabrication and crystallization behaviors of sputtered Ni–Cu–P films on tool steel. Surf Coat Technol. 2001; 139: 233-43.

- Baptista A, Silva F, Porteiro J, Míguez J, Pinto G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement and market trend demands. Coatings. 2018; 8: 402.

- Savisalo T, Lewis DB, Luo Q, Bolton M, Hovsepian P. Structure of duplex CrN/NbN coatings and their performance against corrosion and wear. Surf Coat Technol. 2008; 202: 1661-7.

- Chen J-Y, Yu G-P, Huang J-H. Corrosion behavior and adhesion of ion-plated TiN films on AISI 304 steel. Mater Chem Phys. 2000; 65: 310-5.

- Merl DK, Panjan P, Cekada M, Macek M. The corrosion behavior of Cr-(C,N) PVD hard coatings deposited on various substrates. Electrochim Acta. 2004; 49: 1527-33.

- Dobrzanski LA, Lukaszkowicz K, Zarychta A, Cunha L. Corrosion resistance of multilayer coatings deposited by PVD techniques onto the brass substrate. J Mater Process Technol. 2005; 164-165: 816-21.

- Merlo AM. The contribution of surface engineering to the product performance in the automotive industry. Surf Coat Technol. 2003; 174-175: 21-6.

- Avelar-Batista JC, Spain E, Letch M, Housden J, Beechey R. Improvements on the wear resistance of high thermal conductivity Cu alloys using an electroless Ni–P coating prior to PVD deposition. Surf Coat Technol. 2006; 201: 4052-7.

- Pogrebnjak A, Smyrnova K, Bondar O. Nanocomposite multilayer binary nitride coatings based on transition and refractory metals: structure and properties. Coatings. 2019; 9: 155.

- PVD-PREVLEK, N.N.A.Z., MORPHOLOGY AND CORROSION PROPERTIES PVD Cr-N COATINGS DEPOSITED ON ALUMINIUM ALLOYS. Mater Tehnol. 2011; 45: 593-7.

- Vennemann A, Stock H-R, Kohlscheen J, Rambadt S, Erkens G. Oxidation resistance of titanium–aluminium–silicon nitride coatings. Surf Coat Technol. 2003; 174-175: 408-15.

- Singh K, Limaye PK, Soni NL, Grover AK, Agrawal RG, Suri AK. Wear studies of (Ti–Al) N coatings deposited by reactive magnetron sputtering. Wear. 2005; 258: 1813-24.

- Cubillos GI, Bethencourt M, Olaya JJ. Corrosion resistance of zirconium oxynitride coatings deposited via DC unbalanced magnetron sputtering and spray pyrolysis-nitriding. Appl Surf Sci. 2015; 327: 288-95.

- Qian JC, Zhou ZF, Zhang WJ, Li KY, Bello I, Martinu L, et al. Microstructure and tribo-mechanical properties of Ti–B–C nanocomposite films prepared by magnetron sputtering. Surf Coat Technol. 2015; 270: 290-8.

- Cai F, Huang X, Yang Q. Mechanical properties, sliding wear and solid particle erosion behaviors of plasma enhanced magnetron sputtering CrSiCN coating systems. Wear. 2015;324-325(0):27-35.

- Nam KH, Jung MJ, Han JG. A study on the high rate deposition of CrNx films with controlled microstructure by magnetron sputtering. Surf Coat Technol. 2000; 131: 222-7.

- Bakonyi I, Tóth-Kádár E, Tarnóczi T, Varga LK, Cziráki á, Geröcs I, et al. Structure and properties of fine-grained electrodeposited nickel. Nanostruct Mater. 1993; 3: 155-61.

- Lauer S, Guan Z, Wolf H, Natter H, Schmelzer M, Hempelmann R, et al. Local magnetic properties of nanocrystalline Ni and Pd-Fe. Nanostruct Mater. 1999; 12: 955-8.

- Andreska J, Maurer C, Bohnet J, Schulz uU. Erosion resistance of electroplated nickel coatings on carbon-fibre reinforced plastics. Wear. 2014;319(1-2):138-44.

- Lammel P, Rafailovic LD, Kolb M, Pohl K, Whitehead AH, Grundmeier G, et al. Analysis of rain erosion resistance of electroplated nickel–tungsten alloy coatings. Surf Coat Technol. 2012;206(8-9):2545-51.

- Xu J, Hattori K, Seino Y, Kojima I. Microstructure and properties of CrN/Si3N4 nano-structured multilayer films. Thin Solid Films. 2002; 414: 239-45.

- Avelar-Batista JC, Spain E, Letch M, Housden J, Beechey R. Improvements on the wear resistance of high thermal conductivity Cu alloys using an electroless Ni–P coating prior to PVD deposition. Surf Coat Technol. 2006; 201: 4052-7.

- Kaciulis S, Mezzi A, Montesperelli G, Lamastra FR, Rapone M, et al. Multi-technique study of corrosion resistant CrN/Cr/CrN and CrN ;: ;C coatings. Surf Coat Technol. 2006; 201: 313-9.

- Fenker M, Balzer M, Jehn HA, Kappl H, Lee J-J, Lee K-H, et al. Improvement of the corrosion resistance of hard wear resistant coatings by intermediate plasma etching or multilayered structure. Surf Coat Technol. 2002; 150: 101-6.

- Lampe T. Plasma surface engineering in the automotive industry—trends and future prospectives. Surf Coat Technol. 2003; 174-175: 1-7.

- Han S, Lin JH, Tsai SH, Chung SC, Wang DY, Lu FH, et al. Corrosion and tribological studies of chromium nitride coated on steel with an interlayer of electroplated chromium. Surf Coat Technol. 2000; 133-134: 460-5.

- Keshavarz Hedayati M, Mahboubi F, Nickchi T. Comparison of conventional and active screen plasma nitriding of hard chromium electroplated steel. Vacuum. 2009; 83: 1123-8.

- Kim D, Kim M, Nam KS, Chang D, Kwon SC. Duplex coating for improvement of corrosion resistance in chromium deposit. Surf Coat Technol. 2003; 169-170: 650-4.

- Aouadi SM, Schultze DM, Rohde SL, Wong K-C, Mitchell KAR. Growth and characterization of Cr2N/CrN multilayer coatings. Surf Coat Technol. 2001; 140: 269-77.

- Pradhan SK, Nouveau C, Vasin A, Djouadi M-A. Deposition of CrN coatings by PVD methods for mechanical application. Surf Coat Technol. 2005; 200: 141-5.

- Hones P, Sanjinés R, Lévy F. Sputter deposited chromium nitride based ternary compounds for hard coatings. Thin Solid Films. 1998; 332: 240-6.

- Kong Q, Ji L, Li H, Liu X, Wang Y, Chen J, et al. Composition, microstructure, and properties of CrN x films deposited using medium frequency magnetron sputtering. Appl Surf Sci. 2011; 257: 2269-74.

- Frafjord JJ. Combinatorial design of nickel-chromium alloys by physical vapor deposition and electron beam welding. 2004.

- Cheng WL, Zhou ZF, Shum PW, Li KY. Effect of Ni addition on the structure and properties of Cr–Ni–N coatings deposited by closed-field unbalanced magnetron sputtering ion plating. Surf Coat Technol. 2013; 229: 84-9.

- Merl DK. MORPHOLOGY AND CORROSION PROPERTIES PVD Cr-N COATINGS DEPOSITED ON ALUMINIUM ALLOYS MORFOLOGIJA IN KOROZIJSKE LASTNOSTI CrN. 2011; 45: 593-7.

- McFarland EW, Weinberg WH. Combinatorial approaches to materials discovery. Trends Biotechnol. 1999; 17: 107-15.

- Bertrand G, Mahdjoub H, Meunier C. A study of the corrosion behaviour and protective quality of sputtered chromium nitride coatings. Surf Coat Technol. 2000; 126: 199-209.

- Zhang S, Sun D, Fu Y, Du H. Recent advances of superhard nanocomposite coatings: a review. Surf Coat Technol. 2003; 167: 113-9.

- Andreska J, Maurer C, Bohnet J, Schulz uU. Erosion resistance of electroplated nickel coatings on carbon-fibre reinforced plastics. Wear. 2014; 319: 138-44.

- Aouadi SM, Schultze DM, Rohde SL, Wong K-C, Mitchell KAR. Growth and characterization of Cr2N/CrN multilayer coatings. Surf Coat Technol. 2001; 140: 269-77.

- Regent F, Musil J. Magnetron sputtered Cr-Ni-N and Ti-Mo-N films: comparison of mechanical properties. Surf Coat Technol. 2001; 142-144: 146-51.

- Kagiyama A, Terakado K, Urao R. Effect of nitriding and TiN coating temperatures on the corrosion resistance of the combined surface modification layer. Surf Coat Technol. 2003; 169-170: 397-400.

- Navinšek B, Panjan P, Milošev I. PVD coatings as an environmentally clean alternative to electroplating and electroless processes. Surf Coat Technol. 1999; 116-119: 476-87.

- Li DJ, Liu F, Wang MX, Zhang JJ, Liu QX. Structural and mechanical properties of multilayered gradient CrN/ZrN coatings. Thin Solid Films. 2006; 506-507: 202-6.

- Hsieh JH, Liang C, Yu CH, Wu W. Deposition and characterization of TiAlN and multi-layered TiN/TiAlN coatings using unbalanced magnetron sputtering. Surf Coat Technol. 1998; 108-109: 132-7.

- Chen L, Du Y, Yin F, Li J. Mechanical properties of (Ti, Al)N monolayer and TiN/(Ti, Al)N multilayer coatings. Int J Refract Met Hard Mater. 2007; 25: 72-6.

- Chen L, Wang SQ, Du Y, Li J. Microstructure and mechanical properties of gradient Ti(C, N) and TiN/Ti(C, N) multilayer PVD coatings. Mater Sci Eng A. 2008; 478: 336-9.

- Huang J-H, Ouyang F-Y, Yu G-P. Effect of film thickness and Ti interlayer on the structure and properties of nanocrystalline TiN thin films on AISI D2 steel. Surf Coat Technol. 2007; 201: 7043-53.